S – Synergize U – Uplift C – Cultivate C – Coach E – Empower S – Share S – Sustain

Synergize: Foster strong connections and collaboration among leaders and potential leaders, understanding that teamwork and unity are key to achieving success.

Uplift: Encourage, support, and inspire others to strive for their best, providing the motivation and guidance necessary to reach their full potential.

Cultivate: Create an environment that promotes growth and learning, investing in the development of new leaders through targeted training and mentorship.

Coach: Offer guidance and constructive feedback that helps individuals refine their skills, overcome challenges, and become better leaders themselves.

Empower: Delegate responsibility and trust in others’ abilities, granting them the autonomy and confidence to make decisions, solve problems, and grow as leaders.

Share: Promote a culture of knowledge-sharing and open communication, ensuring that wisdom and experience are passed down to future generations of leaders.

Sustain: Commit to the ongoing development and support of leaders, fostering a strong leadership pipeline that ensures organizational success for years to come.

Does It Really Depend on Other People?

A leader’s success depends on other people for several reasons:

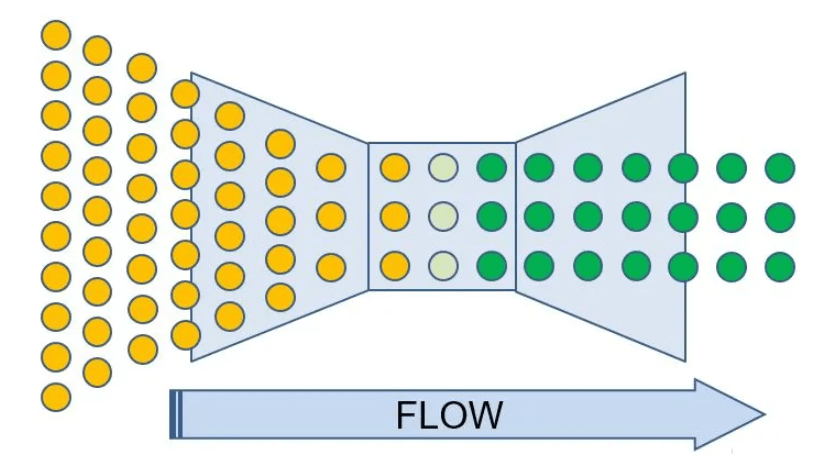

- Collective Efforts: Leadership is about guiding and influencing a group of individuals towards a shared goal. The success of a leader relies on the collective efforts of the team. The leader’s role is to harness the strengths, skills, and knowledge of the team members and channel them towards achieving the desired outcome.

- Collaboration: A leader cannot be an expert in every field or possess all the skills required to address every challenge. They need to rely on the expertise and collaboration of their team members to tackle complex problems, innovate, and make informed decisions.

- Empowerment: Leaders succeed when they empower others, delegate tasks, and trust in their team members’ abilities. This not only leads to higher productivity but also creates a positive work environment that fosters growth, learning, and job satisfaction.

- Emotional Intelligence: A leader’s success often depends on their ability to connect with others, understand their needs, and provide support. By building strong relationships and trust, leaders can inspire and motivate their team members to perform at their best.

- Adaptability: The ability to adapt to change is crucial for a leader’s success. By relying on the input and feedback from their team members, leaders can recognize when changes are needed and implement the necessary adjustments to stay on track towards their goals.

- Learning and Development: No leader knows everything, and continuous learning is essential for growth and success. By fostering a culture of knowledge-sharing and learning from their team members, leaders can expand their own skills, perspectives, and understanding of the challenges they face.

- Accountability: A leader’s success also depends on holding themselves and their team members accountable for the results they produce. By creating a sense of responsibility and ownership, leaders can ensure that everyone stays focused and committed to achieving their goals.

In summary, a leader’s success is highly dependent on other people because leadership is a collaborative process that involves uniting the skills, knowledge, and efforts of a team to achieve a common goal. This requires effective communication, trust, empowerment, and adaptability, all of which involve interacting with and relying on others.