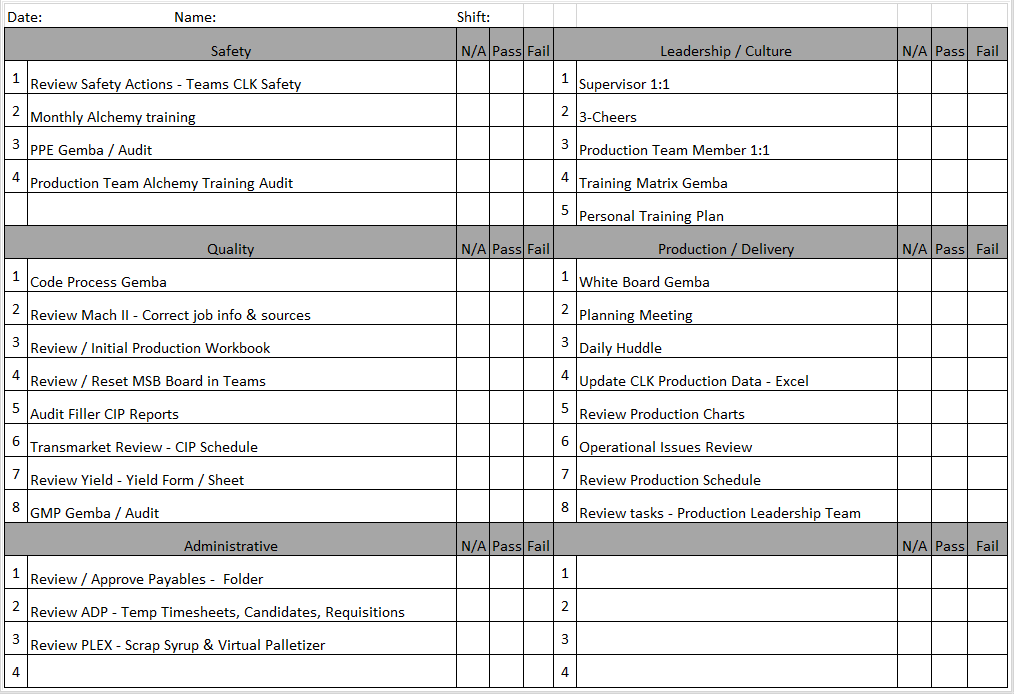

One of the main tasks of operations leadership is enhancing efficiency and productivity. As a Production Manager, I’ve experienced firsthand the time-consuming nature of paper inspections. These manual processes often divert valuable time away from critical team interactions and strategic problem-solving.

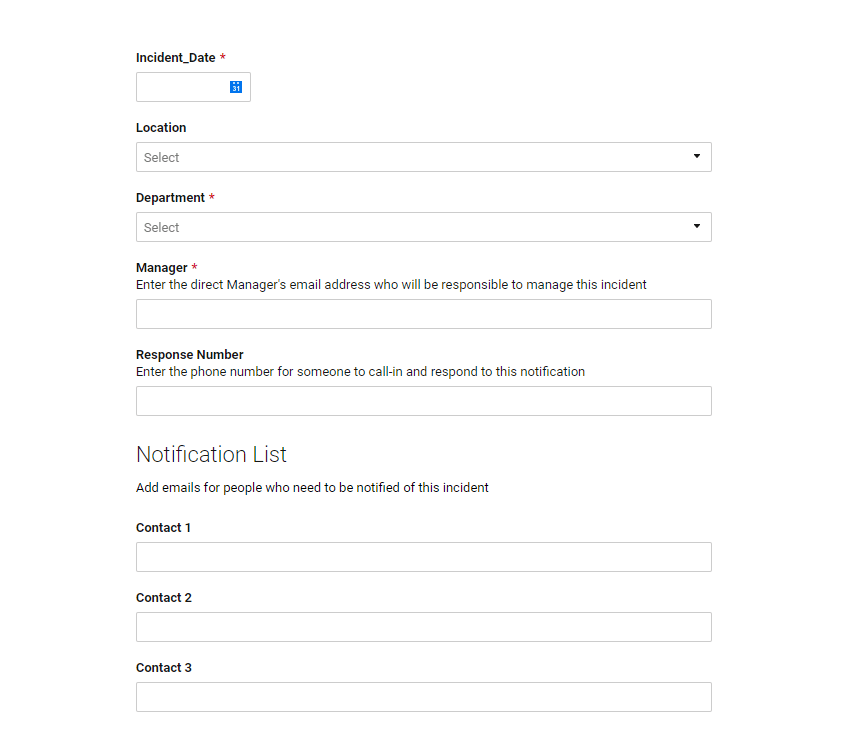

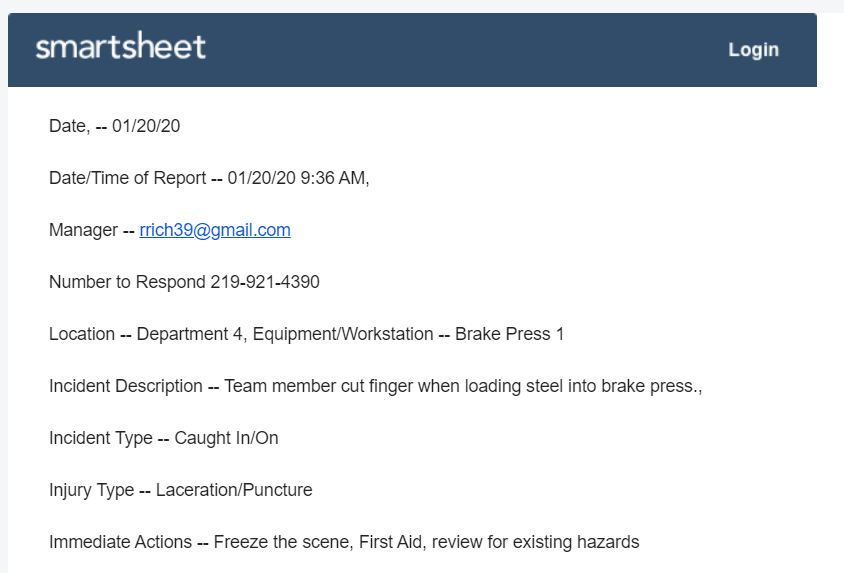

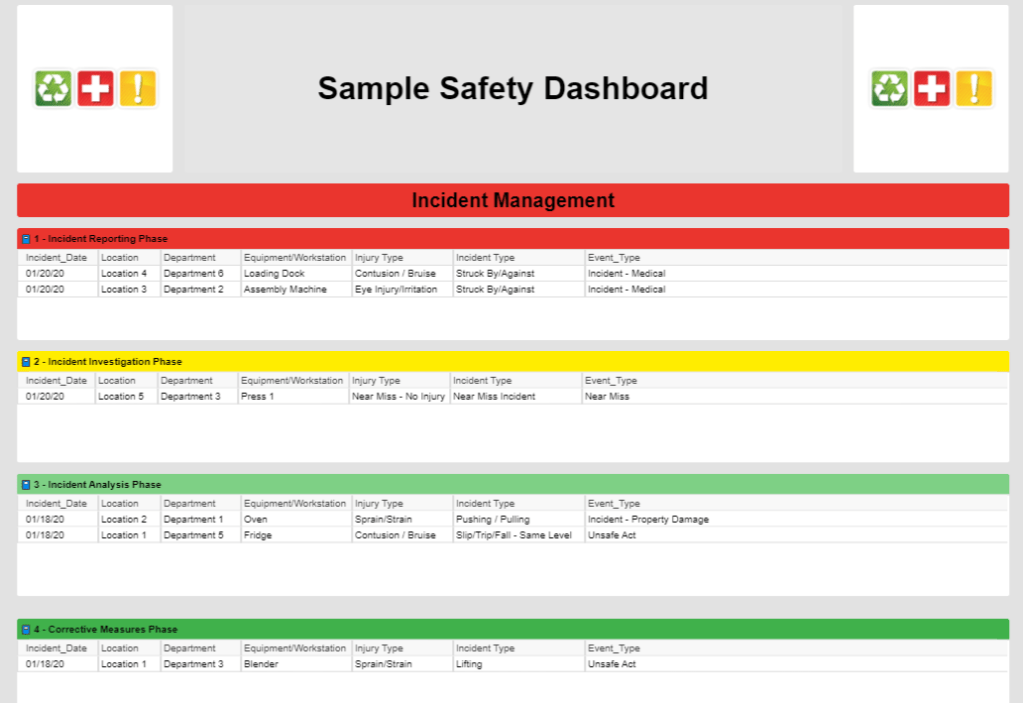

To address this, I’ve implemented automation for our quality checks. This shift from manual paperwork to automated processes not only streamlines operations but also frees up operations leaders to focus on problem-solving and team development. Embracing automation allows us to invest more in our people and cultivate a strong organizational culture.

Table of Contents

- The Power of Standardization in Automation

- Liberating Operations Leaders to Lead and Inspire

- Real-World Examples

- Conclusion: The Human Side of Automation

The Power of Standardization in Automation

Standardizing automation involves creating consistent, repeatable processes managed by automated systems. This reduces variability, minimizes errors, and ensures high-quality outcomes. As highlighted by Harvard Business Review, “Standardizing processes is a crucial step in leveraging the full potential of automation. It creates a stable foundation upon which innovative and creative work can thrive.”

Liberating Operations Leaders to Lead and Inspire

Automating routine tasks allows operations leaders to focus on strategic activities and team development. Here’s how this transformation benefits the organization:

Enhanced Employee Engagement

Operations leaders who have the time to engage with their teams can foster stronger relationships and create a more inclusive work environment. They can better understand employees’ needs, aspirations, and challenges, leading to more personalized and effective leadership. According to Harvard Business Review, “Automation of administrative tasks frees managers to focus on coaching and development, significantly boosting team engagement.”

Building a Positive Culture

Trust, communication, and shared values form the bedrock of a strong organizational culture. Freed from administrative burdens, operations leaders can invest in team-building exercises, open forums, and one-on-one meetings, fostering a sense of belonging and shared purpose. As noted by Harvard Business Review, “Culture-building activities are essential in both traditional and hybrid work environments.”

Encouraging Innovation

With less focus on routine tasks, operations leaders can cultivate a culture of innovation. They can encourage teams to think creatively, experiment with new ideas, and take calculated risks. “When managers are freed from routine tasks, they can better support innovation and creativity within their teams,” emphasizes a Harvard Business Review article.

Personal and Professional Development

Operations leaders with more time for mentoring and coaching can significantly impact their team’s growth. By providing regular feedback, setting clear goals, and supporting professional development, they help employees reach their full potential. As stated in Harvard Business Review, “Investing in the professional development of employees not only enhances their skills but also boosts morale and job satisfaction.”

Real-World Examples

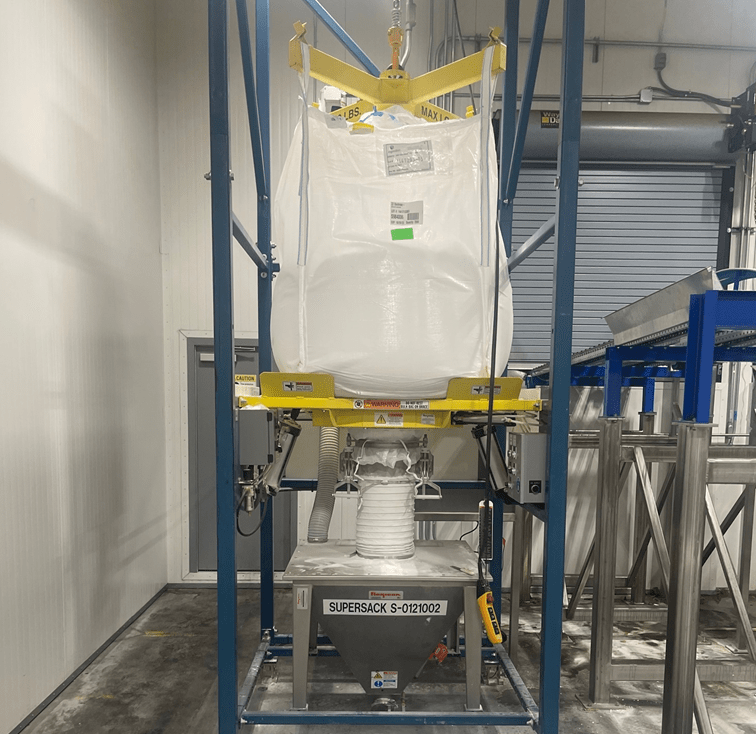

The benefits of this approach are evident in many organizations. Toyota’s adoption of standardized automation in manufacturing has enabled operations leaders to concentrate more on their teams, fostering a culture of continuous improvement and employee development.

In the tech industry, companies like Google and Microsoft use automation to handle repetitive coding and testing tasks. This allows operations leaders and senior engineers to focus on innovative projects and mentoring junior staff, promoting a collaborative and growth-oriented environment.

Conclusion: The Human Side of Automation

While automation and standardization are often viewed through the lens of efficiency and productivity, their true value lies in freeing up human potential. By automating routine tasks, operations leaders can focus on what truly matters—people. They can build stronger relationships, foster a positive culture, and drive innovation, ultimately leading to a more engaged and motivated workforce.

As we continue to embrace automation, it’s essential to recognize that its greatest benefit is not just in performing tasks but in creating time and space for human connection and growth. This balance of technology and humanity is what will drive organizations towards sustainable success.