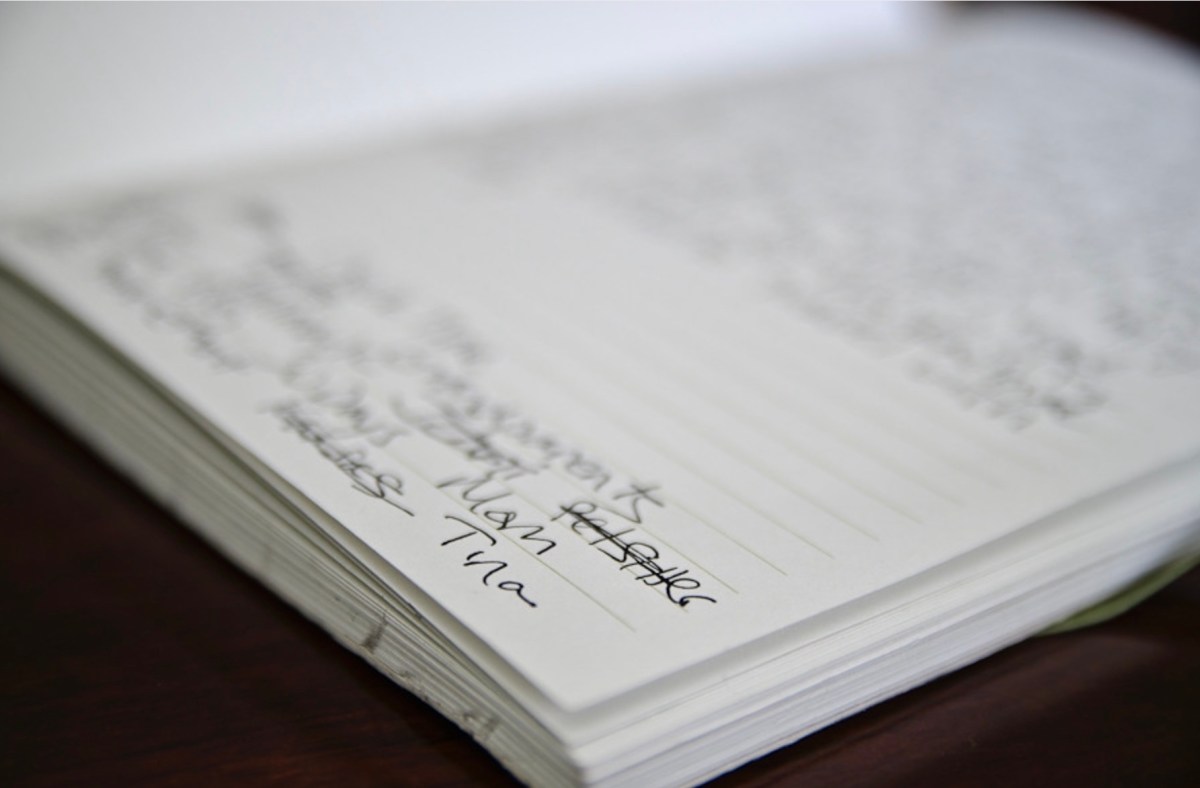

Congratulations. You are joining an elite group of people who recognize the importance and value of keeping a personal journal. I have found this to be one of my core personal habits. It is the one thing that keeps me centered psychologically, emotionally, and spiritually. I have found a freedom to express thoughts and feelings that prior to having a journal, I would never entertain thinking about.

My journal is my safe place. There is no judgment in its pages. Just freedom to be me, to express, and to be transparent and vulnerable. It is in this habit of freeing my mind to be open and honest that I have discovered the real person hiding deep down inside.

I hope to help you in your journey and to shorten the time between the choice to pursue the habit of writing and the realization of the value and benefits of the practice. What follows are four tips or words of advice to do just that. I welcome you to this side of the universe! Welcome to the world of journaling.

Tip 1 – Have a Purpose for Your Journal

The first bit of advice is to define your purpose. Why do you want to journal? What was happening at the exact time that made you think “I’d like to begin the habit of journaling?”

There are many possible reasons but they usually center around a few:

- Capture life moments to share with your family later

- Personal development

- Creative outlet

- Emotional expression

- Personal healing

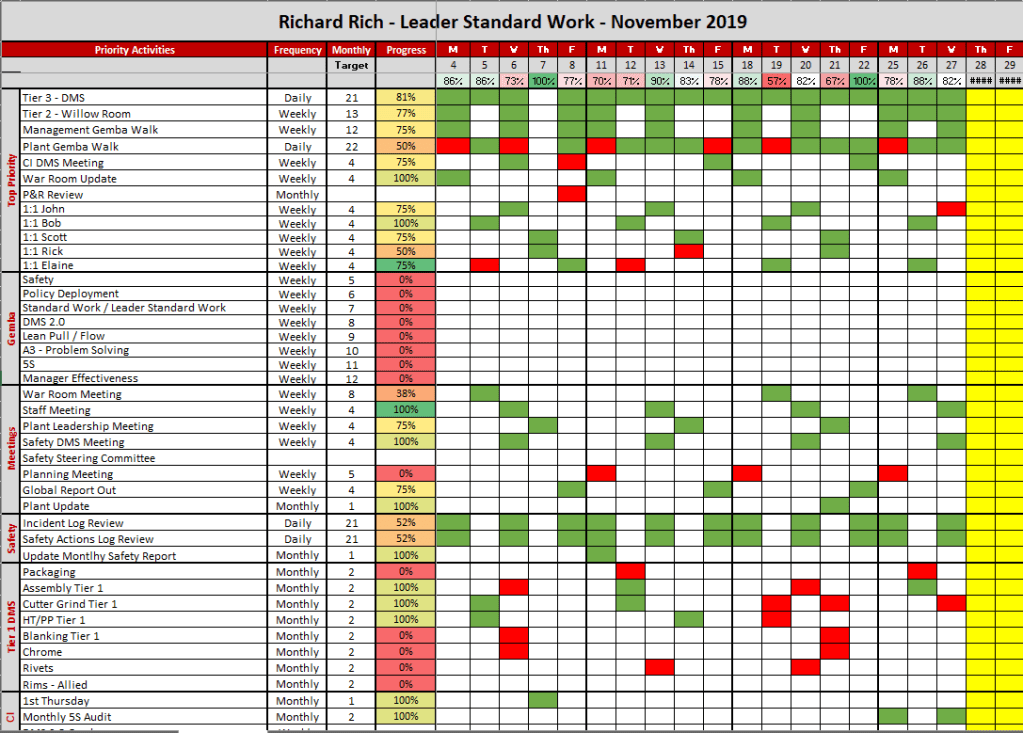

- Professional effectiveness

The benefits of the habit of daily writing and reflection are well known. In fact, one piece of data I recently came across noted that people who journal (write their goals down) are 95% more likely to accomplish them.

The missing piece, however, is the challenge like any new thing that we start, is to stick with it once you’ve started. We will walk through some other tips in this blog the the first and beginning tip is to be clear on your purpose. Know why you want to begin the habit of regular journaling.

Tip 2 – Realize a Value From Journaling

Like anything else, it will be new. This tip is especially important if keeping a journal is something you have always wanted to do and told yourself you would. In fact, it is probable that you may have already tried and started to journal but gave up the habit shortly into the pages. That is okay. I did the same thing.

Unless you receive some type of satisfaction or intangible value from the time and creative energy you put into regular writing, it becomes a chore. No one likes chores – especially me. If, however, you find a value that is greater than the effort, the process of journaling becomes less dependent on rigor and grit and ends up being enjoyable. Avoid the feeling that it is just a regimen at all costs. Every time you start and stop something it becomes harder to start over again. This is because our brains will bring up the memory of our past failed attempts. The negative self-talk may be more than enough to discourage you from doing the one thing to get you out of your rut and take you to the next level.

Tip 1 informed us that we have to know why we are journaling – what do we want out of it. Now we need to get the value out of what we wanted. So in this step, we are going to define the value. It is very simple. Complete the phrase “Journaling will be good for me because _______________.” This is how you will measure value. This will result in the pleasure principle in your mind that will actually release chemicals in your system that tell you “This feels good.” You will experience an increase in the desire not only to journal more frequently but to increase the breadth of content that you are writing about.

Remember this key tip – Your Journaling Has to Add Value.

Tip 3 – Fit Journaling With Your Creative Style.

I am currently on my 6th completed journal (book). Several before them were started but never finished. They included pages with dates or calendars preprinted on them, daily planner items, specific productivity formats, and other help by various publishers. They ranged from the more professional/executive style to the student/homework planning style. They are all good and I don’t mean to downplay the effectiveness of the content, format, or creative genius of the authors.

I found that preset formats were very limiting for my creative mind. This was learned over time. The reason I chose the formatted styles was being a novice, I had no idea what to write. I would sit down, open the cover to the next page and – BLANK! I didn’t know what to say. It was funny because It felt like there were so many thoughts rolling around in my head that they could barely be kept together but when it came time to write there was nothing coming out of my pen.

I hate the feeling of failure or ineffectiveness. Approaching the journaling process with a preset format was the crutch to get me over the hump. I would fill in the blanks as best I could by checking off the boxes that the publishing company thought would work for me but at the end of the day, it still didn’t click. It was like I was filling out someone else’s journal. It became cumbersome and a chore like we talked about in Tip 2. Since I didn’t know what to write or how to write it I depended on someone else’s style to dictate how my thoughts would be captured in my journal.

Fortunately, you will not have to experience this. We are going to help you be able to sit down and begin a journal that will be yours. It will fit with the way your mind works. It will fit your creative style. In essence – it will be a reflection of who you are!

For now, avoid journals with formatted pages or content. We need to discover how our minds operate and express thoughts and ideas. You will see that as you free yourself up and let your mind go while holding your pencil or pen, the pages will fill easily as the creative flow is unleashed on blank pages.

The best way to begin is to sit and just record the day and time. Write it down. Next, briefly describe how you feel right now. Don’t mince words. Just be open and honest. Are you tired? Are you frustrated about life or work? Are you experiencing anxiety about your relationships. No need to qualify. Just write it down. Don’t worry if your words are many or few. It doesn’t matter. More words will come as your mind gets used to the newfound freedom.

Next, briefly describe what your day looks like. What is your biggest challenge today? How are you or how will you be prepared to handle it? Write it down.

Lastly, write down a phrase of affirmation. Something that you would say to a friend if they were walking in your shoes right now. Encourage that person. Later on in the evening, you will return to your journal to reflect on the day and receive the words of encouragement.

Tip 4 – Create a Journaling Habit

To get the most value of your personal journal it must become a regular practice. Developing a routine of journaling will, at first, seem like registering for a gym membership right after New Year’s Day. We have already covered the first three elements to take the chore-like feeling out of journaling. Since you will have a purpose (Tip – 1), it will be adding value (Tip – 2), and it will be a reflection of who you are as a person (Tip – 3), The final key is to commit to the routine of journaling. Having covered the first three steps, the time required for the adoption of journaling from a routine to a habit where your mind goes into automatic “journal mode” will be shortened significantly. You will find the time very satisfying and invigorating to the point that you will begin carving out and protecting that time; prioritizing it over old habits that are actually destructive to your personal development. I don’t like coaching people to “develop a habit of …” because habits are a result. If it were that easy to “develop a habit” everyone would be accomplishing everything they started. The process of developing a habit is not easy but it is simple. The key is repetition. Just do it.

A few answers to these questions will help you decide when and where to write in your journal: What is your best time of the day – when are you the most attentive and creative? Do it then. Try the early morning before anyone else is up. If that doesn’t work then try another time. Keep trying until it clicks.

Summary

It seems hard. You don’t know what to write. That’s okay. Everyone starts that way. Just go buy a nice journal. Keep it private. Sit down and write. Use the tips above and see if shortly you come to really enjoy your time and can’t understand why other people don’t journal themselves.

I’d love some feedback on this. What have been your challenges or what have you been experience while you journal?